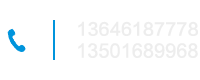

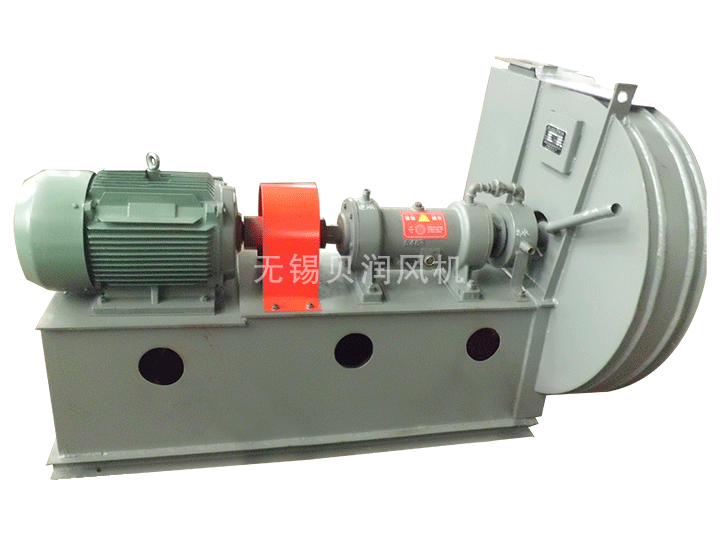

High temperature centrifugal fan

High temperature centrifugal fan to do the method of balancing

In the new dry process production line, the installed capacity of various models accounts for 30% ~ 40% of the total power of the production line. It is very important to strengthen the maintenance and maintenance of the online centrifugal fan, especially the serious wear of the fan impeller, Balance, which led to the increase in the size of the fan, seriously affecting the normal operation of the production Therefore, how to do in the construction site for the fan to do the balance and clear the imbalance factors in the years of fan maintenance management, the author summed up a set of Effective simple drawing method is used to find the impulse point of the impulse point position, and in the light position to add weight to clear the fan imbalance

Method introduction

To the rotor rotor to do the balance, the key is to find the impeller light point position, and determine the weight of the counterweight used to find a balance, the specific steps are as follows:

(1) to open the fan, stable operation, can reflect the vibration of the fan point M (such as bearing, etc.), with the vibration meter measured amplitude A0, recorded after the shutdown

(2) the impeller front (or rear) circumference 3 equal parts, respectively, as 1:00, 2:00, 3:00

(3) at 1:00 folder pre-made a good chuck P (according to the size of the fan impeller to determine its quality, usually mp = 150 g ~ 300 g), repeat step 1, measured M point amplitude A1

(4) Replace the position of the chuck P to 2 o'clock and 3 o'clock, repeat step 3, and measure the amplitude of the M points A2, A3

(5) plotted with A0 as the radius for the circle, the center of the O, the circle of three equal points, respectively, as O1 point, O2 point, O3 points; to O1 as the center, A1 for the radius for the arc; , A2 for the radius for the arc; to O3 as the center, A3 for the radius of the arc for the three arc were B, C, D three points

(6) for the BCD of the core O4, O4 point is the point, to connect OO4 and extend the intersection O in O5 point, O5 point is added with heavy iron point of the point OO4 length L, the O5 point with The weight is m = mp × A0 / 2L

(7) in the fan wheel front (or rear) circumference to find the actual O5 point position, the weight of m with iron block welding, thus, centrifugal fan to complete the balance.

In the new dry process production line, the installed capacity of various models accounts for 30% ~ 40% of the total power of the production line. It is very important to strengthen the maintenance and maintenance of the online centrifugal fan, especially the serious wear of the fan impeller, Balance, which led to the increase in the size of the fan, seriously affecting the normal operation of the production Therefore, how to do in the construction site for the fan to do the balance and clear the imbalance factors in the years of fan maintenance management, the author summed up a set of Effective simple drawing method is used to find the impulse point of the impulse point position, and in the light position to add weight to clear the fan imbalance

Method introduction

To the rotor rotor to do the balance, the key is to find the impeller light point position, and determine the weight of the counterweight used to find a balance, the specific steps are as follows:

(1) to open the fan, stable operation, can reflect the vibration of the fan point M (such as bearing, etc.), with the vibration meter measured amplitude A0, recorded after the shutdown

(2) the impeller front (or rear) circumference 3 equal parts, respectively, as 1:00, 2:00, 3:00

(3) at 1:00 folder pre-made a good chuck P (according to the size of the fan impeller to determine its quality, usually mp = 150 g ~ 300 g), repeat step 1, measured M point amplitude A1

(4) Replace the position of the chuck P to 2 o'clock and 3 o'clock, repeat step 3, and measure the amplitude of the M points A2, A3

(5) plotted with A0 as the radius for the circle, the center of the O, the circle of three equal points, respectively, as O1 point, O2 point, O3 points; to O1 as the center, A1 for the radius for the arc; , A2 for the radius for the arc; to O3 as the center, A3 for the radius of the arc for the three arc were B, C, D three points

(6) for the BCD of the core O4, O4 point is the point, to connect OO4 and extend the intersection O in O5 point, O5 point is added with heavy iron point of the point OO4 length L, the O5 point with The weight is m = mp × A0 / 2L

(7) in the fan wheel front (or rear) circumference to find the actual O5 point position, the weight of m with iron block welding, thus, centrifugal fan to complete the balance.