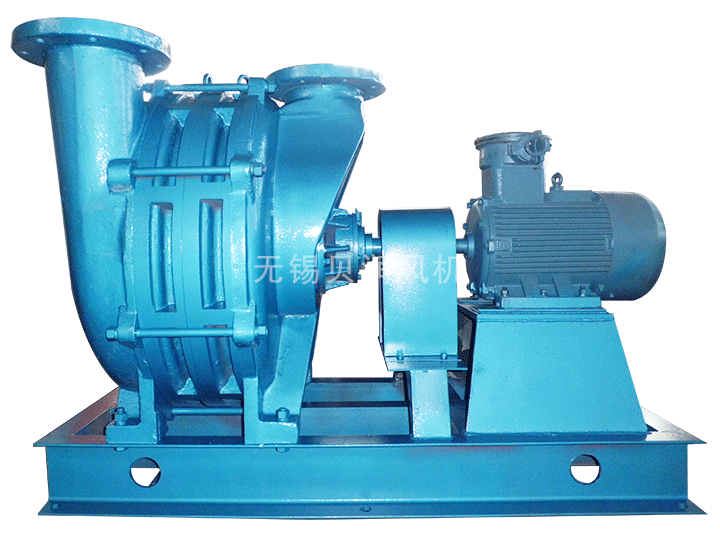

Multi stage centrifugal fan

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

-

Multi stage centrifugal fan

MORE+

Product Introduction

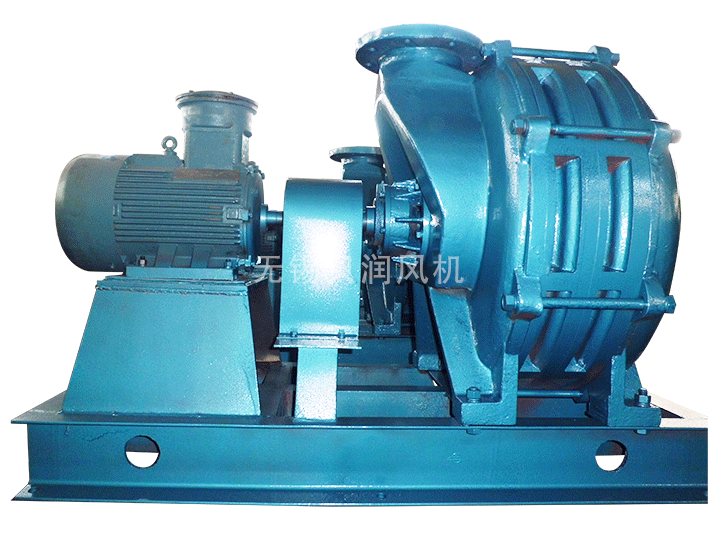

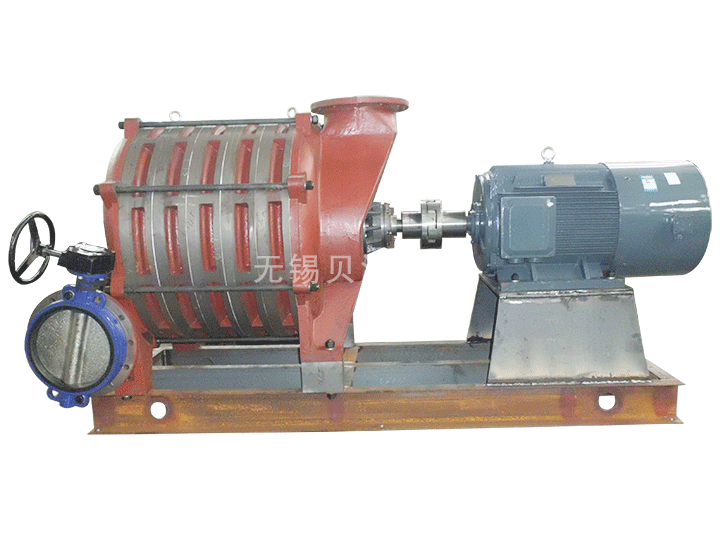

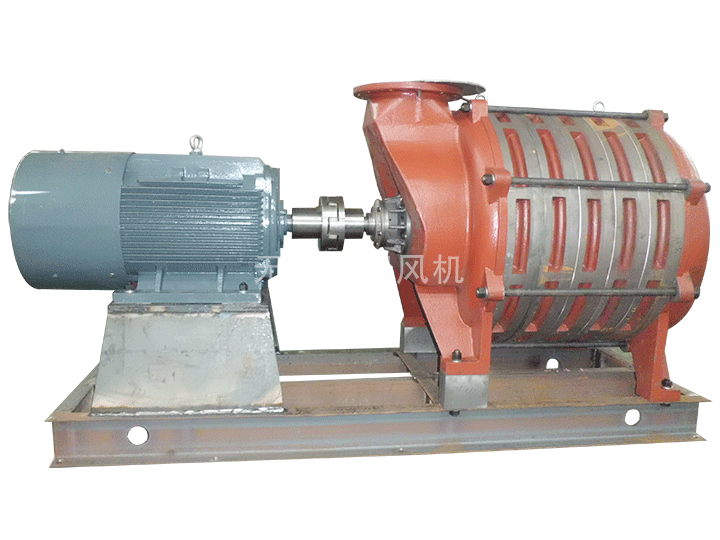

Multi-stage centrifugal blower is the introduction of German technology, combined with China's national conditions developed by the domestic nearly a thousand sewage treatment plants (stations), steel, petrochemical, power, paper, medicine, cement, coal and other enterprises to adopt mature products. Multi-stage centrifugal blower with multi-stage, bearing external, low speed, tandem, single suction, double support, import and export direction up or left (from the TV side) and other structures, belonging to the world's leading product level.

Main technical specifications

Import flow: 15 ~ 100m ³ / min

Export pressure: 1000 ~ 1500m H2O

Vacuum degree: -800-5000mmH2O

Ambient temperature: -35 ~ + 40 ℃

Relative humidity: 20 to 85%

Noise: ≤ 83dB (A)

Bearing vibration value: vibration speed ≤ 4.7mm / S

Fan selection

1, import flow.

2, export pressure.

3, the inlet temperature (maximum temperature).

4, import pressure (local atmospheric pressure).

5, water depth.

6, aeration resistance.

7, pipeline and loss of network.

(Only when the sewage treatment to consider 5,6,7 three elements)

Features

1, compact structure: beautiful appearance, good stability. Easy installation and maintenance.

2, smooth operation: the optimal design of the impeller to reduce the axial force to a minimum, and a high efficiency of the impeller, and static and dynamic balance correction, so that the machine running smoothly, without any vibration device in the case of bearing Amplitude ≤ 0.04mm.

3, the noise is low: the blower running, without any mechanical friction, the use of reasonable leaf-shaped lines to minimize the sound. Multi-stage centrifugal blower noise is high frequency noise, as long as there are obstacles, you can sound insulation, so the fan room almost no noise.

4, oil-free machinery: Blower bearing grease lubrication, bearing life of more than two years. The fan does not produce oil and gas in operation. Special requirements of the fan, the use of lithium molybdenum disulfide grease lubrication bearings.

5, Impeller: impeller with a special composite line, reducing the internal leakage, improve the volumetric efficiency.

6, easy to adjust: the import side of the butterfly valve to adjust the flow, the export side of the butterfly valve to adjust the pressure.

7, drive mode: usually use two asynchronous motor, you can also use four motor drive. Depending on the user's power grid, different voltage motors can be used.

8, sealed: each impeller in addition to the import circle, the stair and the chassis at both ends with a labyrinth seal to prevent gas leakage.

9, cooling: exhaust bearing with air-cooled and water-cooled two structures, due to impeller on the gas step by step compression, resulting in exhaust temperature is much higher than the intake housing. In the exhaust bearing seat with air-cooled or water-cooled device to extend the bearing life.

10, bearing temperature control alarm: fan accessories with temperature control box, through the PT100 resistance connected to the bearing, when the bearing temperature exceeds the set temperature, the temperature control box will automatically alarm.

11, transmission: a coupling drive, belt drive, gearbox drive three. According to different equipment and technology, use different transmission methods.

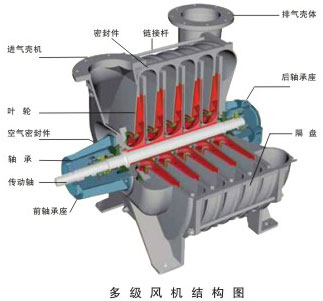

Structure and characteristics

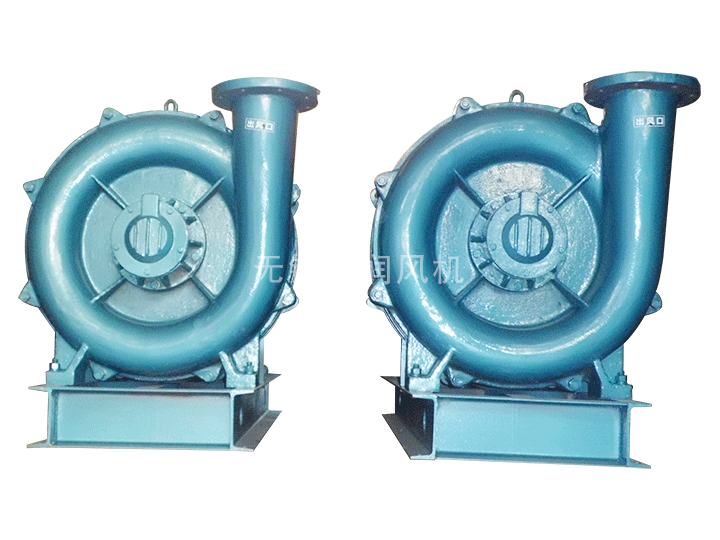

chassis

Shell material using HT250 castings, after aging and thermal processing to ensure the strength and stability of the molecular structure of the material. The main components of the chassis by the intake box, the middle of the partition, the exhaust shell, they are sealed with rubber seals, and through the kerosene leakage test to ensure that the gas does not leak. Impeller at the exit with diffuser, with a return device at the entrance to ensure the efficiency of the blower. In order to meet the different requirements of the pressure and flow, the blower series can be used to level 2 -10 compression. Inlet and outlet position According to the needs of users, the motor can be installed in the inlet side; can also be installed in the exhaust side; flange surface can be vertical up, but also horizontal to the left.

Multi-stage centrifugal blower is the introduction of German technology, combined with China's national conditions developed by the domestic nearly a thousand sewage treatment plants (stations), steel, petrochemical, power, paper, medicine, cement, coal and other enterprises to adopt mature products. Multi-stage centrifugal blower with multi-stage, bearing external, low speed, tandem, single suction, double support, import and export direction up or left (from the TV side) and other structures, belonging to the world's leading product level.

Main technical specifications

Import flow: 15 ~ 100m ³ / min

Export pressure: 1000 ~ 1500m H2O

Vacuum degree: -800-5000mmH2O

Ambient temperature: -35 ~ + 40 ℃

Relative humidity: 20 to 85%

Noise: ≤ 83dB (A)

Bearing vibration value: vibration speed ≤ 4.7mm / S

Fan selection

1, import flow.

2, export pressure.

3, the inlet temperature (maximum temperature).

4, import pressure (local atmospheric pressure).

5, water depth.

6, aeration resistance.

7, pipeline and loss of network.

(Only when the sewage treatment to consider 5,6,7 three elements)

Features

1, compact structure: beautiful appearance, good stability. Easy installation and maintenance.

2, smooth operation: the optimal design of the impeller to reduce the axial force to a minimum, and a high efficiency of the impeller, and static and dynamic balance correction, so that the machine running smoothly, without any vibration device in the case of bearing Amplitude ≤ 0.04mm.

3, the noise is low: the blower running, without any mechanical friction, the use of reasonable leaf-shaped lines to minimize the sound. Multi-stage centrifugal blower noise is high frequency noise, as long as there are obstacles, you can sound insulation, so the fan room almost no noise.

4, oil-free machinery: Blower bearing grease lubrication, bearing life of more than two years. The fan does not produce oil and gas in operation. Special requirements of the fan, the use of lithium molybdenum disulfide grease lubrication bearings.

5, Impeller: impeller with a special composite line, reducing the internal leakage, improve the volumetric efficiency.

6, easy to adjust: the import side of the butterfly valve to adjust the flow, the export side of the butterfly valve to adjust the pressure.

7, drive mode: usually use two asynchronous motor, you can also use four motor drive. Depending on the user's power grid, different voltage motors can be used.

8, sealed: each impeller in addition to the import circle, the stair and the chassis at both ends with a labyrinth seal to prevent gas leakage.

9, cooling: exhaust bearing with air-cooled and water-cooled two structures, due to impeller on the gas step by step compression, resulting in exhaust temperature is much higher than the intake housing. In the exhaust bearing seat with air-cooled or water-cooled device to extend the bearing life.

10, bearing temperature control alarm: fan accessories with temperature control box, through the PT100 resistance connected to the bearing, when the bearing temperature exceeds the set temperature, the temperature control box will automatically alarm.

11, transmission: a coupling drive, belt drive, gearbox drive three. According to different equipment and technology, use different transmission methods.

Structure and characteristics

chassis

Shell material using HT250 castings, after aging and thermal processing to ensure the strength and stability of the molecular structure of the material. The main components of the chassis by the intake box, the middle of the partition, the exhaust shell, they are sealed with rubber seals, and through the kerosene leakage test to ensure that the gas does not leak. Impeller at the exit with diffuser, with a return device at the entrance to ensure the efficiency of the blower. In order to meet the different requirements of the pressure and flow, the blower series can be used to level 2 -10 compression. Inlet and outlet position According to the needs of users, the motor can be installed in the inlet side; can also be installed in the exhaust side; flange surface can be vertical up, but also horizontal to the left.

Rotor

Rotor by the spindle, impeller, labyrinth seal bearing, balance plate, semi-coupling composition. Spindle using high-quality carbon shaft made of steel and modulated to ensure that the tensile strength, bending strength. Impeller diameter of 800mm below the use of aluminum alloy precision centrifugal casting, diameter of 800mm or more using high-strength alloy steel welded together, and through ultrasonic testing. 1% impeller is higher than the time speed of 15% of the super-speed test, a single impeller for static balance test, the entire rotor dynamic balance correction to ensure that the vibration speed is less than or equal to 4.3mm / s, balance plate used to offset the impeller before and after the disk policy The axial pressure difference.

The company to customer needs as their responsibility to create various forms of matching impeller, radial, forward tilting, tilting.

Motor

Motor for the blower drive supporting equipment, by the domestic large-scale motor enterprises or Sino-foreign joint ventures production. Standard configuration using IP44 or IP54 ordinary motor. Special needs can be used when the outdoor type, explosion-proof, dust-proof, waterproof and other motor, in the absence of electricity occasions, can also be used engine or steam turbine drive. BD series drive for the belt drive; BD series of transmission for the coupling direct drive.

Bearing seat

The bearing material is HT250 cast iron, which is heat treated and machined. For ease of maintenance and repair, the bearing is bolted to the outside of the housing, as long as the bearing can be replaced by the bearing. Blower bearing with high temperature molybdenum disulfide lithium grease lubrication, large blower bearings using high-grade lubricating oil lubrication, and with a special oil seal to ensure that the bearing seat is not oil. As the exhaust case temperature is high, the exhaust end bearing seat with air-cooled and water-cooled form of the bearing cooling (air cooling refers to the body after the shaft end of the labyrinth seal out of a small amount of gas, water-cooled refers to tap water or cycle Water) to extend the bearing life. Front and rear bearing are equipped with thermocouple, connected to the axis of digital display sound and light alarm, the normal operation of the bearing temperature display, when the bearing temperature error automatically alarm.

Bearing for the standard rolling bearings, all have foreign imports.

Scope of supply

1, the host part: centrifuge fan theme

2, the annex part: matching motor, common base, foot bolts, the import side of the filter muffler, the import side of the manual butterfly valve.

3, optional parts: the export side of the muffler, the export side of the butterfly valve (manual or electric), vent valve, vent silencer, adjustable pipe, flexible joints, check valves, elbow, outdoor fan, motor rain cover

4, optional control part: star delta start cabinet, automatic step-down start cabinet, soft start start cabinet, frequency start cabinet, the main control cabinet (PLC) control box.

Precautions for use

Timely maintenance and repair lubrication system, the use of clean lubricants, full lubrication of the bearing parts, is to ensure the extension of the important life of the fan measures. When the initial use of the fan, pay attention to check whether the deterioration of oil; with or without moisture, pay attention to check the oil chamber lubricants should not be less than the required one-half, so as not to start after the lack of oil. But can not let the oil room too much oil and lead to excessive bearing temperature.

Note that you must use lithium-based grease or molybdenum disulfide oil, do not use calcium-based grease.

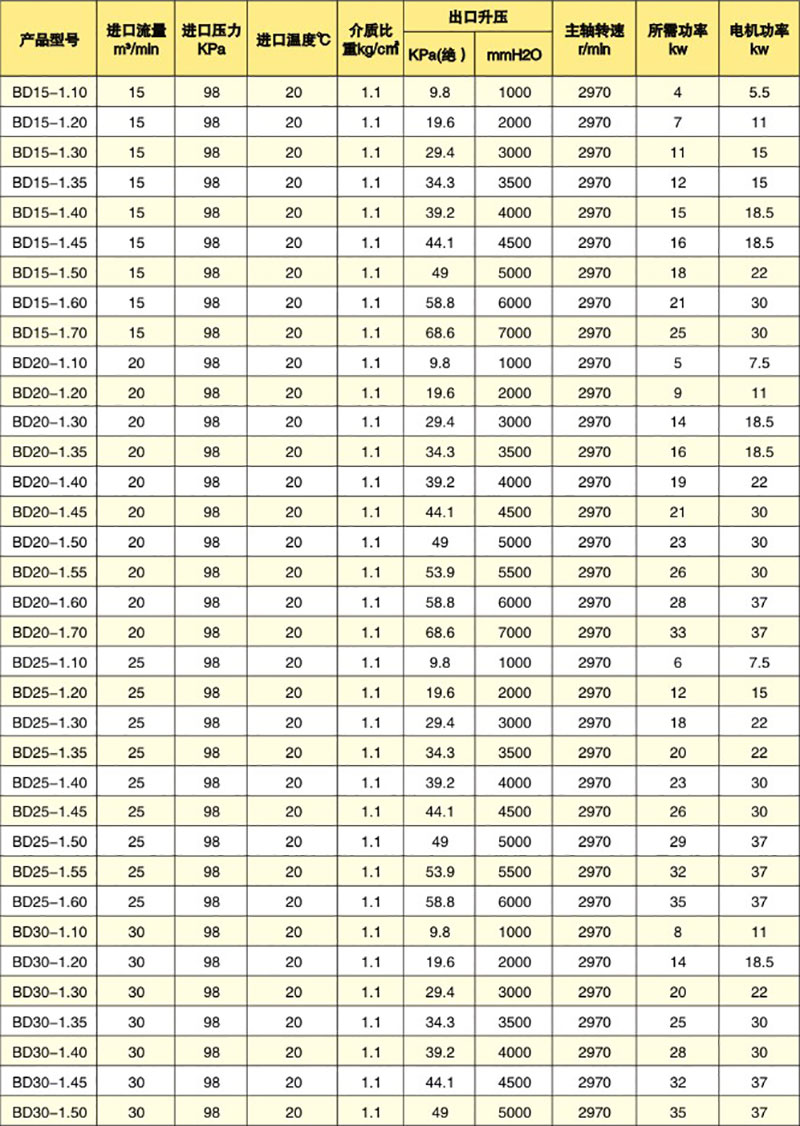

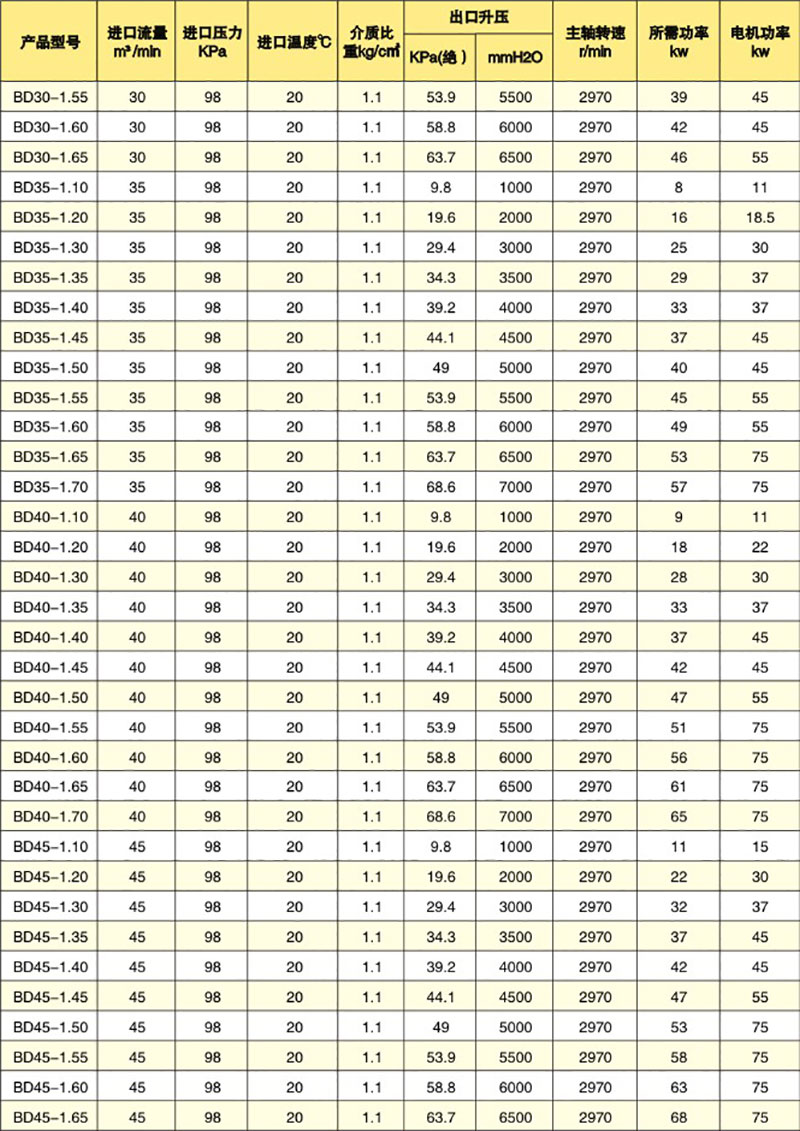

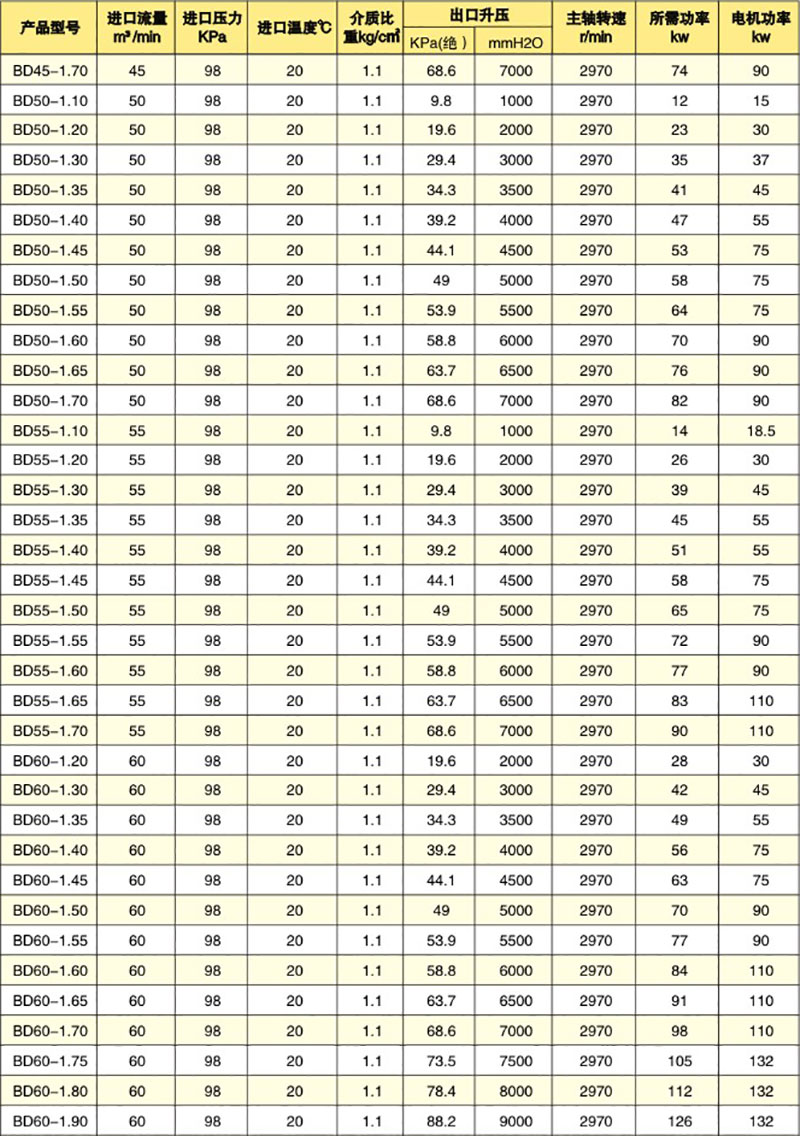

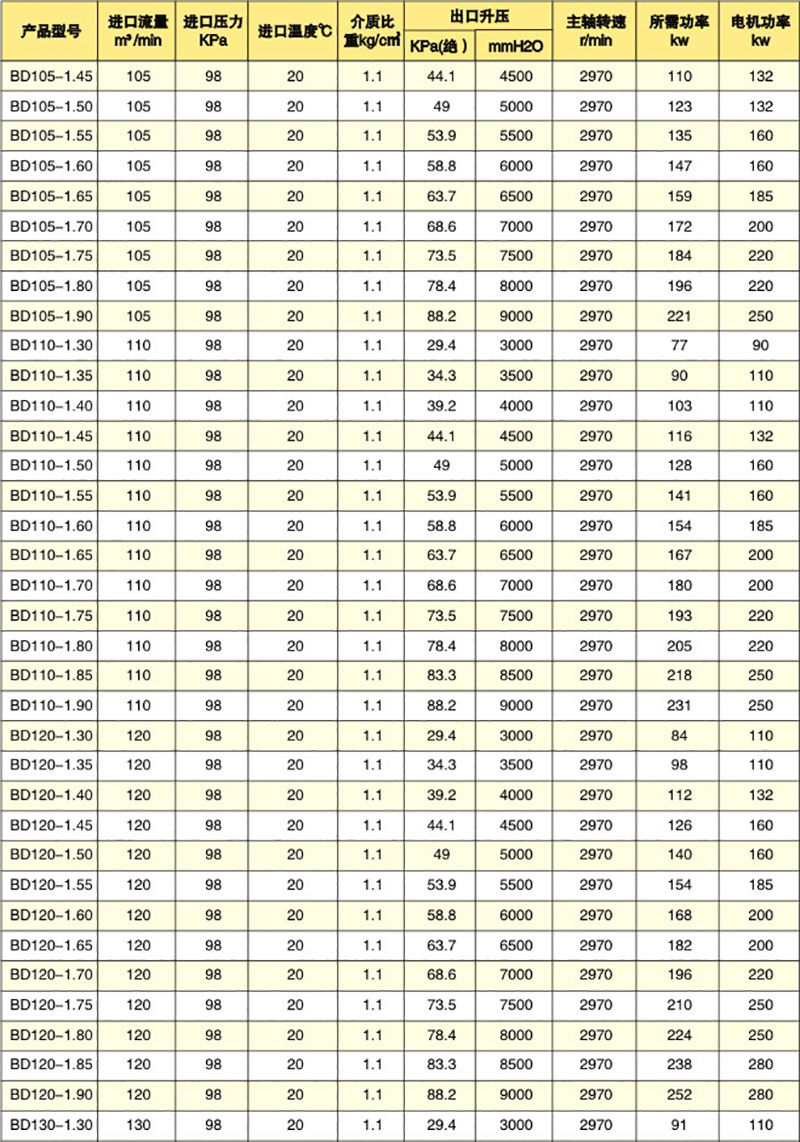

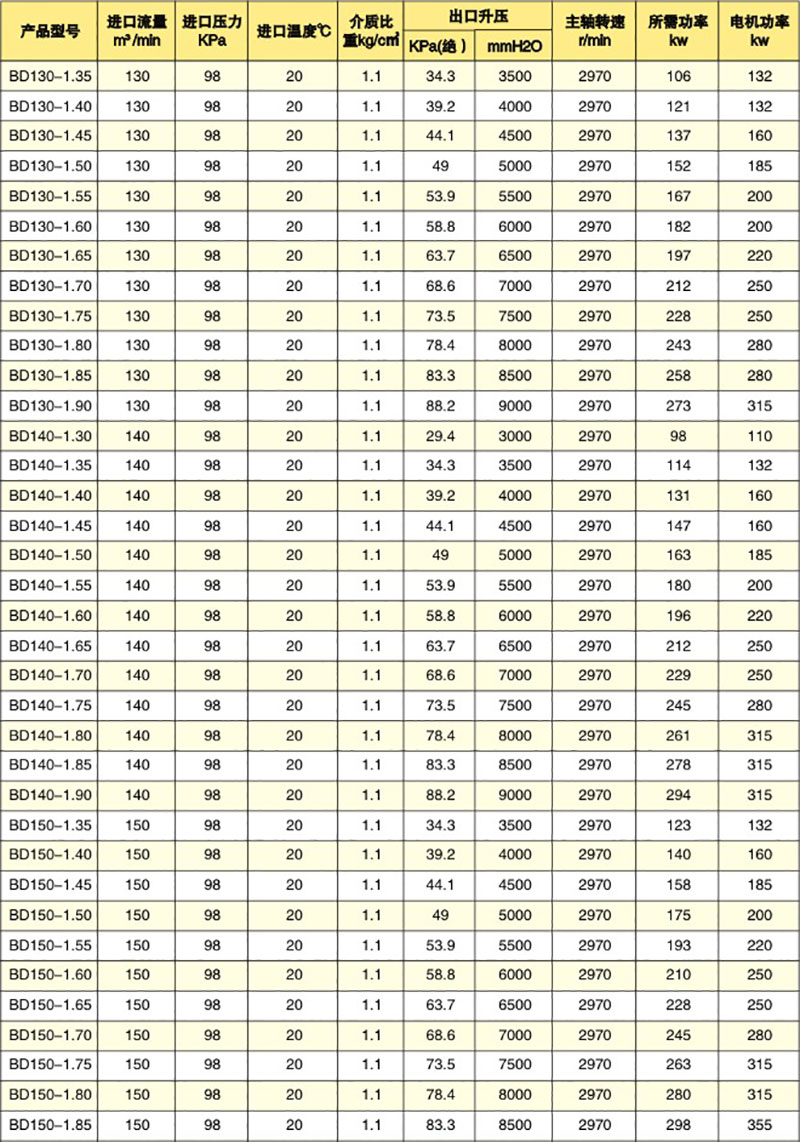

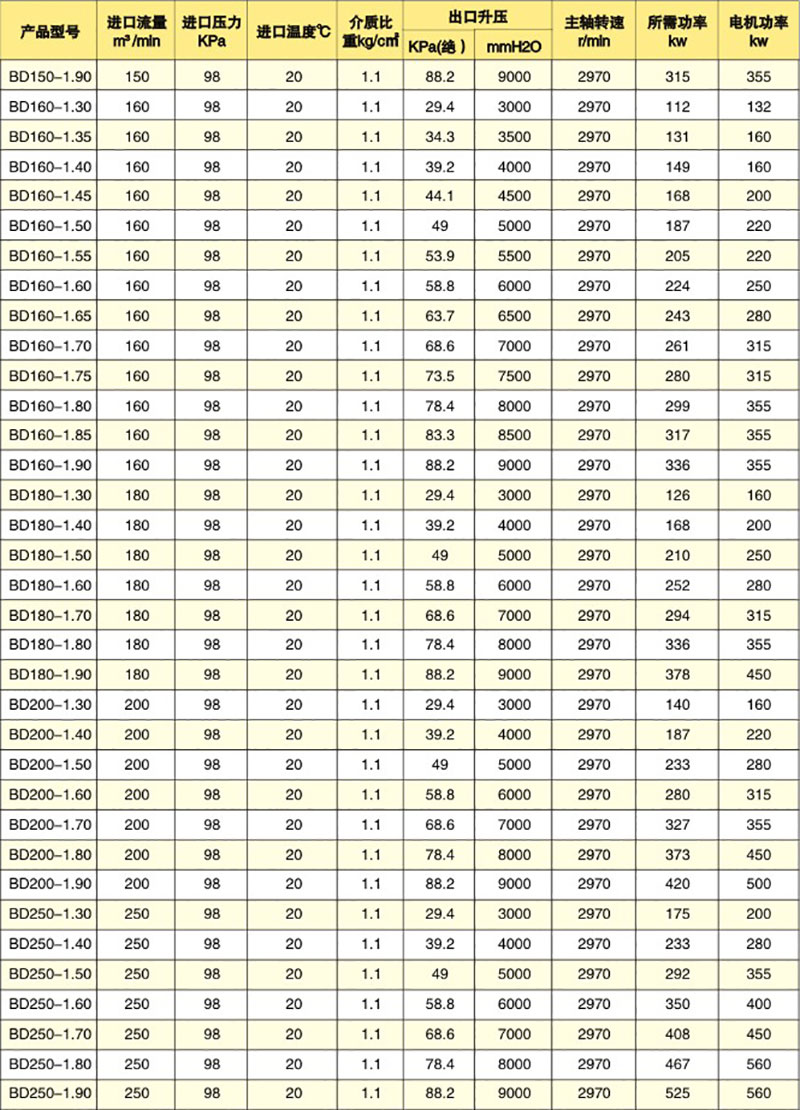

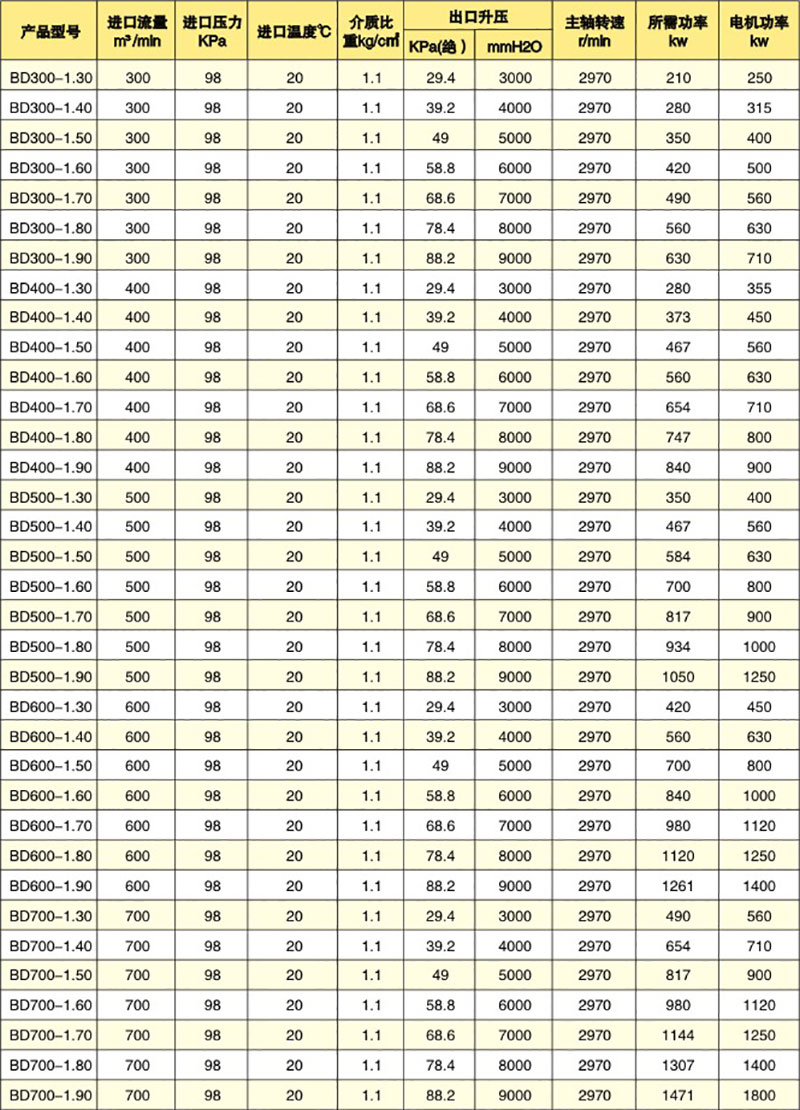

Multi - stage centrifugal fan parameter table

Rotor by the spindle, impeller, labyrinth seal bearing, balance plate, semi-coupling composition. Spindle using high-quality carbon shaft made of steel and modulated to ensure that the tensile strength, bending strength. Impeller diameter of 800mm below the use of aluminum alloy precision centrifugal casting, diameter of 800mm or more using high-strength alloy steel welded together, and through ultrasonic testing. 1% impeller is higher than the time speed of 15% of the super-speed test, a single impeller for static balance test, the entire rotor dynamic balance correction to ensure that the vibration speed is less than or equal to 4.3mm / s, balance plate used to offset the impeller before and after the disk policy The axial pressure difference.

The company to customer needs as their responsibility to create various forms of matching impeller, radial, forward tilting, tilting.

Motor

Motor for the blower drive supporting equipment, by the domestic large-scale motor enterprises or Sino-foreign joint ventures production. Standard configuration using IP44 or IP54 ordinary motor. Special needs can be used when the outdoor type, explosion-proof, dust-proof, waterproof and other motor, in the absence of electricity occasions, can also be used engine or steam turbine drive. BD series drive for the belt drive; BD series of transmission for the coupling direct drive.

Bearing seat

The bearing material is HT250 cast iron, which is heat treated and machined. For ease of maintenance and repair, the bearing is bolted to the outside of the housing, as long as the bearing can be replaced by the bearing. Blower bearing with high temperature molybdenum disulfide lithium grease lubrication, large blower bearings using high-grade lubricating oil lubrication, and with a special oil seal to ensure that the bearing seat is not oil. As the exhaust case temperature is high, the exhaust end bearing seat with air-cooled and water-cooled form of the bearing cooling (air cooling refers to the body after the shaft end of the labyrinth seal out of a small amount of gas, water-cooled refers to tap water or cycle Water) to extend the bearing life. Front and rear bearing are equipped with thermocouple, connected to the axis of digital display sound and light alarm, the normal operation of the bearing temperature display, when the bearing temperature error automatically alarm.

Bearing for the standard rolling bearings, all have foreign imports.

Scope of supply

1, the host part: centrifuge fan theme

2, the annex part: matching motor, common base, foot bolts, the import side of the filter muffler, the import side of the manual butterfly valve.

3, optional parts: the export side of the muffler, the export side of the butterfly valve (manual or electric), vent valve, vent silencer, adjustable pipe, flexible joints, check valves, elbow, outdoor fan, motor rain cover

4, optional control part: star delta start cabinet, automatic step-down start cabinet, soft start start cabinet, frequency start cabinet, the main control cabinet (PLC) control box.

Precautions for use

Timely maintenance and repair lubrication system, the use of clean lubricants, full lubrication of the bearing parts, is to ensure the extension of the important life of the fan measures. When the initial use of the fan, pay attention to check whether the deterioration of oil; with or without moisture, pay attention to check the oil chamber lubricants should not be less than the required one-half, so as not to start after the lack of oil. But can not let the oil room too much oil and lead to excessive bearing temperature.

Note that you must use lithium-based grease or molybdenum disulfide oil, do not use calcium-based grease.

Multi - stage centrifugal fan parameter table