Stainless steel Roots blower

Brief

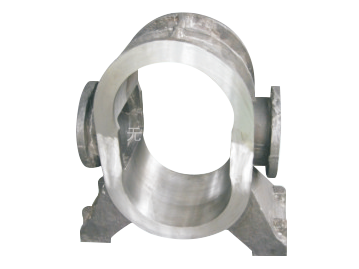

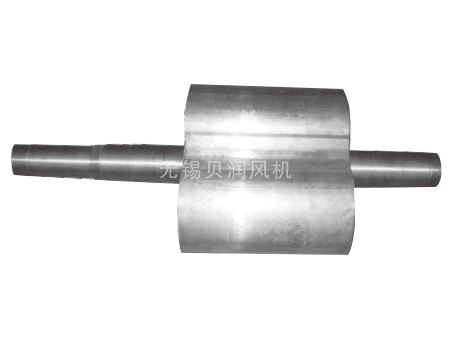

In the production practice found that the use of formaldehyde tail gas instead of steam, and sometimes silver catalyst surface layer of yellow matter. It is well known that the entry of impurities such as iron will cause CO2 to rise. In the entire exhaust cycle of the system, the duct is basically all the use of stainless steel, and fans in foreign countries such as Indonesia, mostly using stainless steel, and in the country is basically a carbon steel fan. Because the exhaust contains a small amount of formaldehyde, inevitably with water, which is particularly sensitive to carbon steel material. If the exhaust gas is carbon steel, then the formaldehyde gas on the exhaust gas inside the fan rotor and cavity wall and other significant corrosive effect, so that the exhaust outlet of the fan may bring iron impurities into the reaction system after the impact of catalyst Activity, elevated CO2, etc., so the exhaust fan is best to use stainless steel fan.

Typical Case

We do the economic accounting: If you increase the exhaust gas circulation system, according to an annual output of 60,000 tons of equipment as an example: the entire exhaust gas circulation system (including stainless steel exhaust fan, pipes, valves, instruments, etc.) increased fixed assets investment 400,000 yuan (about 1.33 yuan /Ton)

Methanol cost increase: 5 kg / ton (14 yuan / ton)

Electricity cost increase: 8 degrees / ton (8 yuan / ton)

Increase the external steam: 300 kg / Tuen (75 yuan / ton)

It can be concluded that the use of exhaust gas cycle, formaldehyde can increase profitability:

75-14-8-1.33 = 51.67 yuan / ton * 60000 tons ≈310 million / year

Investment recovery: 400000/3100000 ≈ 1.5 months

In summary, to formaldehyde instead of steam as a heat stabilizer can be economically reasonable production of formaldehyde. When the methanol concentration is 84.4%, the concentration of formaldehyde in the product is slightly higher than 50%; when the methanol concentration is 90%, the formaldehyde concentration can reach 54%; when the methanol concentration is 95%, the formaldehyde concentration can reach 58%. It is also possible to adjust the oxygen to alcohol ratio and the reaction temperature arbitrarily in the production, to optimize the conversion and selectivity to the optimum oxygen and oxygen temperature to achieve optimum consumption.

The use of stainless steel fan as the exhaust fan, can rule out the exhaust on the fan corrosion, so that the entire exhaust gas circulation system without leaving hidden danger, the formaldehyde tail gas replacement to maximize the benefits of water vapor.

In the production practice found that the use of formaldehyde tail gas instead of steam, and sometimes silver catalyst surface layer of yellow matter. It is well known that the entry of impurities such as iron will cause CO2 to rise. In the entire exhaust cycle of the system, the duct is basically all the use of stainless steel, and fans in foreign countries such as Indonesia, mostly using stainless steel, and in the country is basically a carbon steel fan. Because the exhaust contains a small amount of formaldehyde, inevitably with water, which is particularly sensitive to carbon steel material. If the exhaust gas is carbon steel, then the formaldehyde gas on the exhaust gas inside the fan rotor and cavity wall and other significant corrosive effect, so that the exhaust outlet of the fan may bring iron impurities into the reaction system after the impact of catalyst Activity, elevated CO2, etc., so the exhaust fan is best to use stainless steel fan.

Typical Case

We do the economic accounting: If you increase the exhaust gas circulation system, according to an annual output of 60,000 tons of equipment as an example: the entire exhaust gas circulation system (including stainless steel exhaust fan, pipes, valves, instruments, etc.) increased fixed assets investment 400,000 yuan (about 1.33 yuan /Ton)

Methanol cost increase: 5 kg / ton (14 yuan / ton)

Electricity cost increase: 8 degrees / ton (8 yuan / ton)

Increase the external steam: 300 kg / Tuen (75 yuan / ton)

It can be concluded that the use of exhaust gas cycle, formaldehyde can increase profitability:

75-14-8-1.33 = 51.67 yuan / ton * 60000 tons ≈310 million / year

Investment recovery: 400000/3100000 ≈ 1.5 months

In summary, to formaldehyde instead of steam as a heat stabilizer can be economically reasonable production of formaldehyde. When the methanol concentration is 84.4%, the concentration of formaldehyde in the product is slightly higher than 50%; when the methanol concentration is 90%, the formaldehyde concentration can reach 54%; when the methanol concentration is 95%, the formaldehyde concentration can reach 58%. It is also possible to adjust the oxygen to alcohol ratio and the reaction temperature arbitrarily in the production, to optimize the conversion and selectivity to the optimum oxygen and oxygen temperature to achieve optimum consumption.

The use of stainless steel fan as the exhaust fan, can rule out the exhaust on the fan corrosion, so that the entire exhaust gas circulation system without leaving hidden danger, the formaldehyde tail gas replacement to maximize the benefits of water vapor.