L series Roots blower

L series Roots blower (1)

The main parts of the material selection

Axis: # 45 or 40Cr, 35CrMo.

Synchronous gear: # 45 or 40Cr, 35CrMo.

Impeller, chassis, wall panels, couplings, bearing, side cover are selected HT20-40 gray cast iron.

Complete sets of supply

Import air purifier, exhaust muffler, shared chassis, loop valve, with remote transmitter pressure gauge, safety valve, check valve, according to user requirements, the factory to undertake the above sets of supply business, welcome users to negotiate.

This product is the most widely used conventional varieties, suitable for pressure to clean air, clean gas.

The biggest feature of this product is smooth operation, the use of safe, low noise, has long been well received by users.

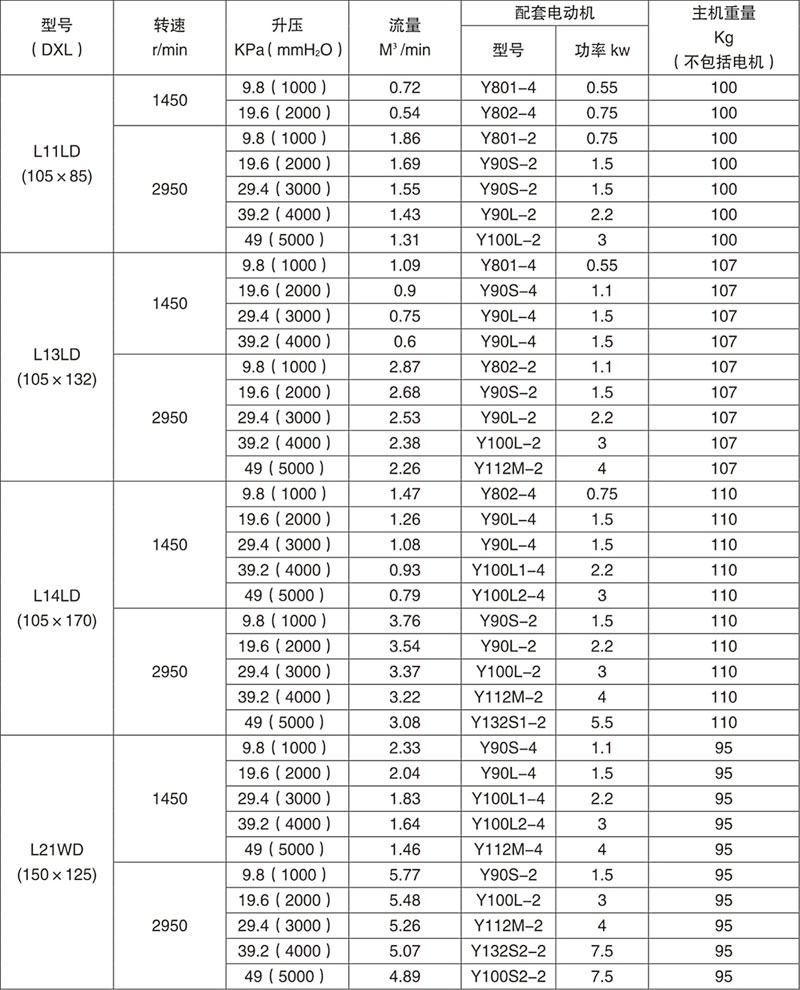

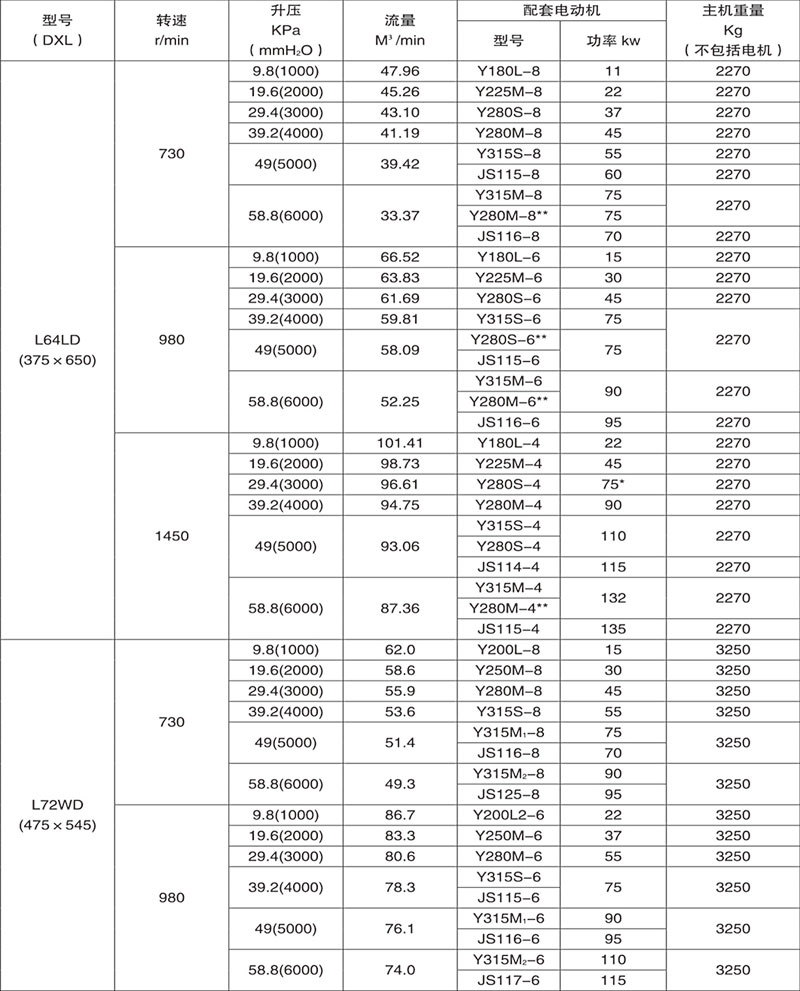

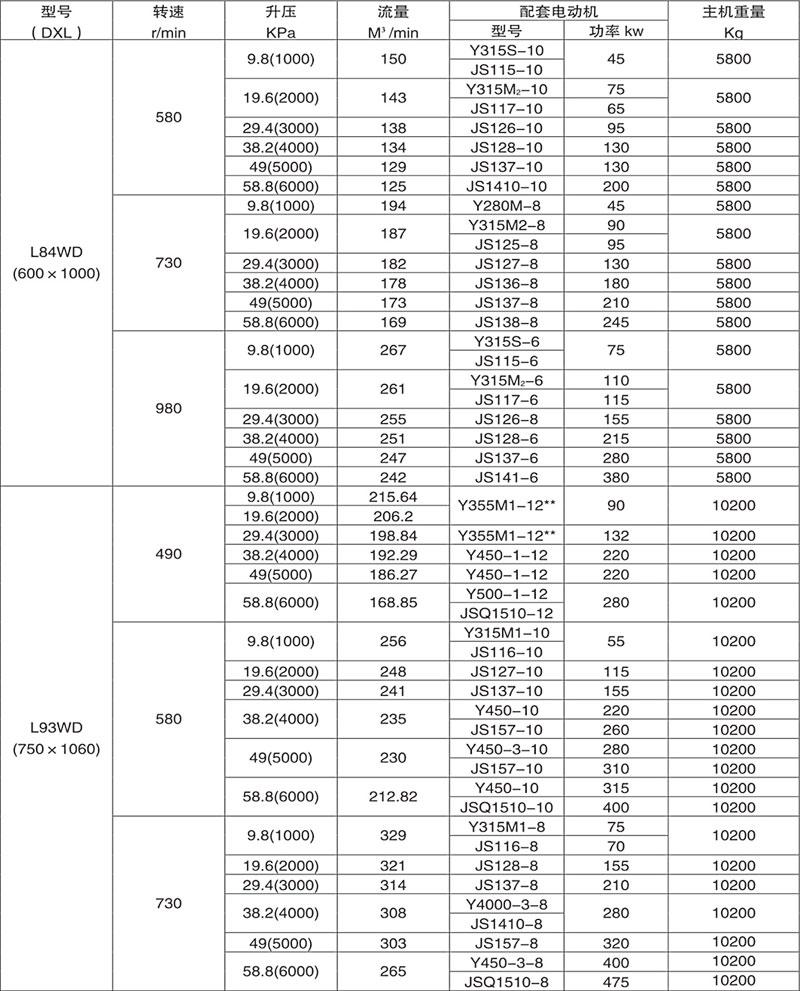

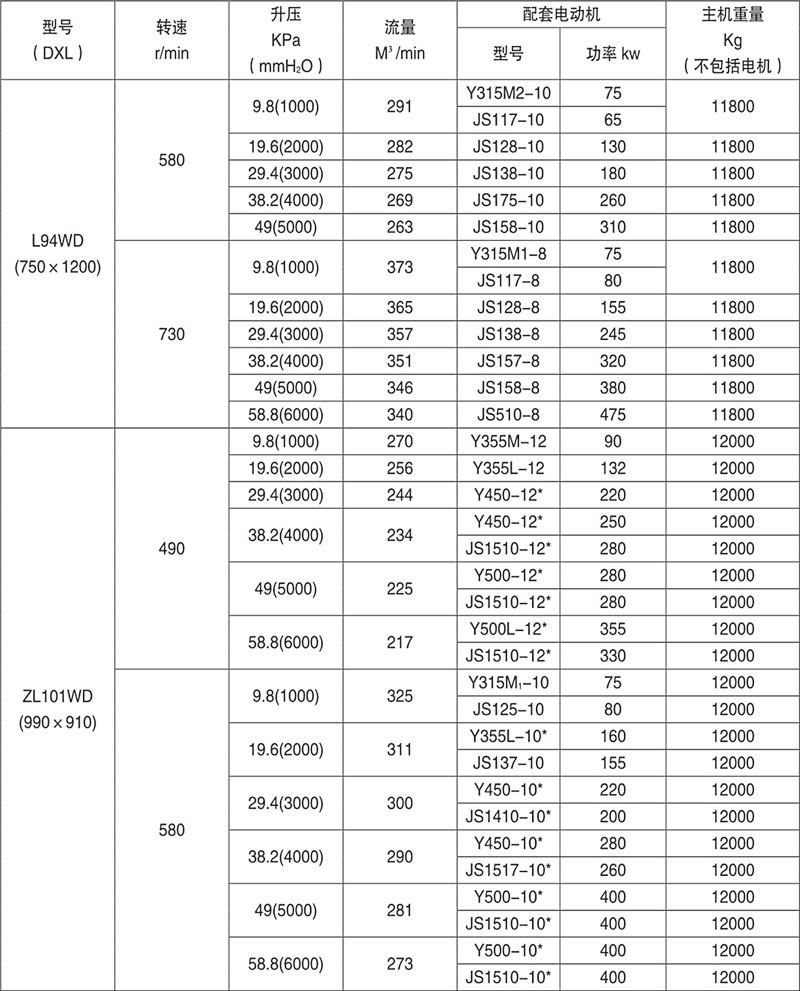

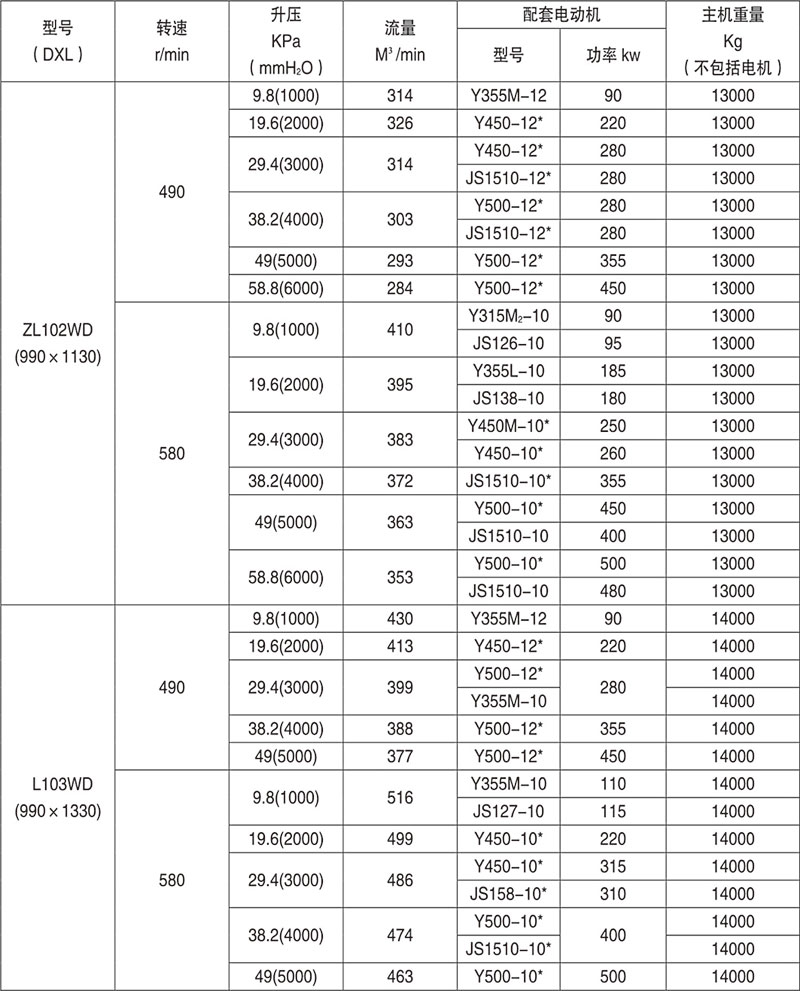

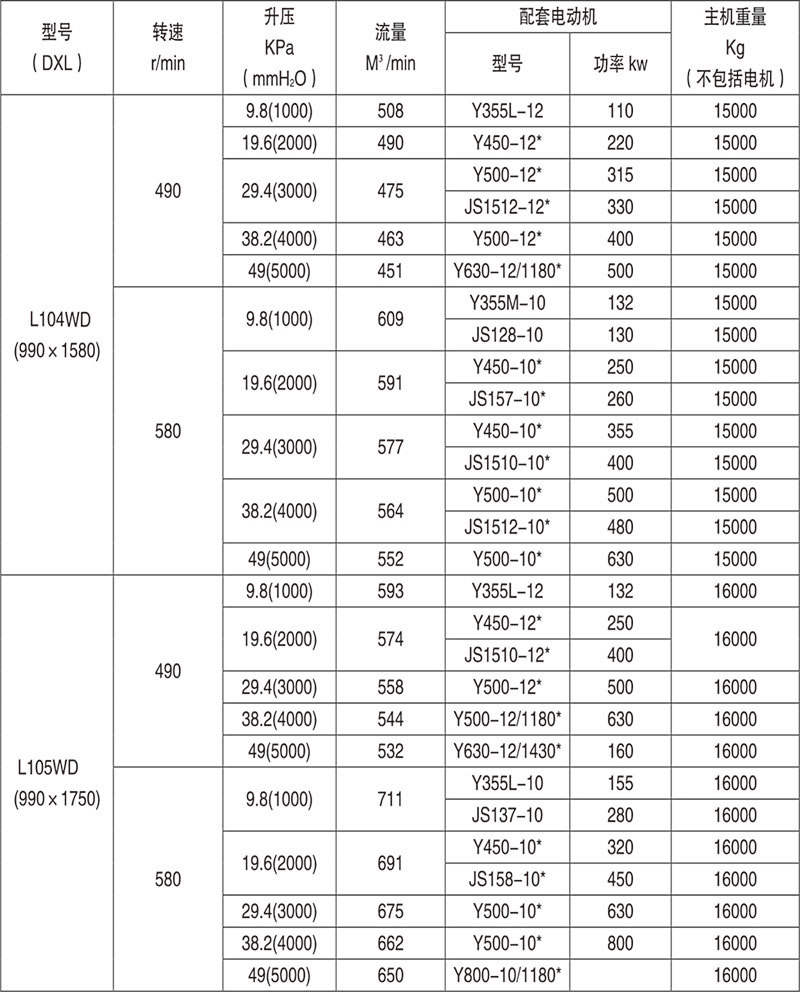

Performance Table (1)

The main parts of the material selection

Axis: # 45 or 40Cr, 35CrMo.

Synchronous gear: # 45 or 40Cr, 35CrMo.

Impeller, chassis, wall panels, couplings, bearing, side cover are selected HT20-40 gray cast iron.

Complete sets of supply

Import air purifier, exhaust muffler, shared chassis, loop valve, with remote transmitter pressure gauge, safety valve, check valve, according to user requirements, the factory to undertake the above sets of supply business, welcome users to negotiate.

This product is the most widely used conventional varieties, suitable for pressure to clean air, clean gas.

The biggest feature of this product is smooth operation, the use of safe, low noise, has long been well received by users.

Performance Table (1)

L series Roots blower (2)

Use

Our factory L series Roots blower transmission medium to clean air, clean gas, sulfur dioxide and other inert gas-based. But also on-demand production of other flammable, explosive, eclipse, toxic and special gases. And thus can be widely used in metallurgy, chemical, fertilizer, petrochemical, video, building materials, oil, mining, textile, gas stations, pneumatic conveying, sewage treatment and other industrial sectors.

L-type Roots blower is a national joint design (part of the company's proprietary) series Roots blower. Product parts versatility, high degree of standardization, reasonable structure, high efficiency, the use of safe and reliable. User selection, installation and maintenance and spare parts spare parts convenient.

L-type Roots blower series of wide coverage. Flow from 0.25-1000m³min, boost up to 98KPa.

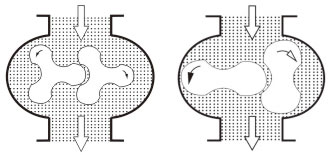

Working principle

The two rotors in the body through the role of synchronous gear, the relative direction of the direction of rotation. In view of the impeller and the impeller between the impeller and the collective between the appropriate working gap, so that the suction chamber and exhaust chamber are isolated from each other, by means of the rotation of the impeller, the stroke of non-internal compression of the body of the gas from the intake chamber After pushing to the exhaust chamber, the exhaust gas reaches the blast.

Use

Our factory L series Roots blower transmission medium to clean air, clean gas, sulfur dioxide and other inert gas-based. But also on-demand production of other flammable, explosive, eclipse, toxic and special gases. And thus can be widely used in metallurgy, chemical, fertilizer, petrochemical, video, building materials, oil, mining, textile, gas stations, pneumatic conveying, sewage treatment and other industrial sectors.

L-type Roots blower is a national joint design (part of the company's proprietary) series Roots blower. Product parts versatility, high degree of standardization, reasonable structure, high efficiency, the use of safe and reliable. User selection, installation and maintenance and spare parts spare parts convenient.

L-type Roots blower series of wide coverage. Flow from 0.25-1000m³min, boost up to 98KPa.

Working principle

The two rotors in the body through the role of synchronous gear, the relative direction of the direction of rotation. In view of the impeller and the impeller between the impeller and the collective between the appropriate working gap, so that the suction chamber and exhaust chamber are isolated from each other, by means of the rotation of the impeller, the stroke of non-internal compression of the body of the gas from the intake chamber After pushing to the exhaust chamber, the exhaust gas reaches the blast.

1, because the impeller in the body running without friction, no lubrication, so that the exclusion of gas without oil. It is chemical, food and other industries the ideal pneumatic transmission gas source.

2, Roots blower is the volume of rotary blower, use, with the pressure changes, the flow of change is very small, but the flow with the speed and change. Therefore, the choice of pressure is wide, the choice of flow can be achieved by selecting the speed.

3, Roots blower speed is higher, the rotor and the rotor, the gap between the rotor and the body is small, so less leakage, volume efficiency than the body high. I plant processing and assembly technology strength, to ensure that the gap is reasonable, uniform, both to achieve a higher volumetric efficiency, and will not make the body due to thermal expansion caused by friction.

4, Roots blower structure determines its mechanical friction loss is very small. Because only the bearings and gears have institutions, in the selection, the rotor, chassis and gear wheels have sufficient mechanical strength, safe operation, long service life is a major feature of the factory Roots blower products.

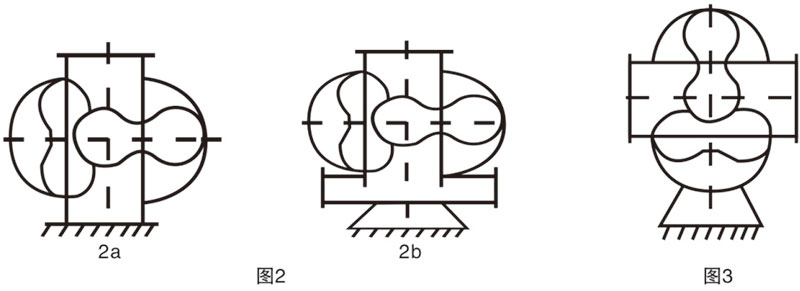

Type

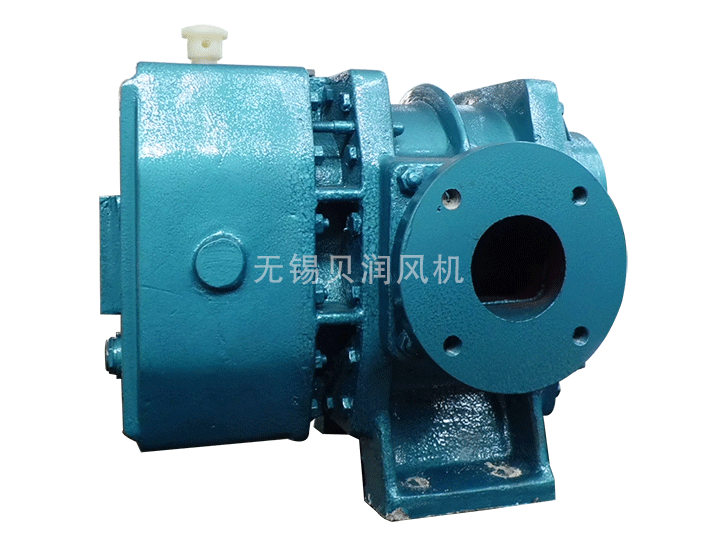

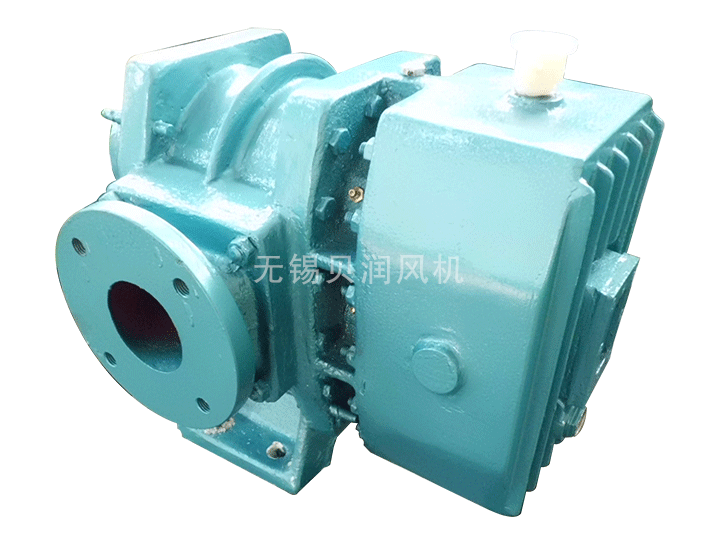

Roots blower of the general type of vertical, horizontal two.

Horizontal - The two rotor centerlines of the blower are in the horizontal plane and the gas flows vertically (as shown in Figures 2a, 2b)

Vertical - the two rotor centerline of the blower in the vertical plane, the air flow for the horizontal flow (shown in Figure 3)

In order to facilitate the user to install and use, L1-L4 small fan with vertical and horizontal dual-use, L5 and L6 for the vertical, L7 to L11 large fan for the horizontal, horizontal structure of the inlet and outlet direction, such as from the strength, Into the next row as well. Our factory, vertical blower have been determined according to the direction of the exhaust to adjust the gap, such as users want to change into the exhaust direction, can be made in the purchase requirements, under the conditions allowed to change the strength.

Structure

Rotor: by the shaft, impeller, bearings, synchronous gear, coupling, sleeve and other components.

Impeller: the use of involute profile, the volume of high efficiency.

Bearing: near the coupling side as the positioning side of the choice of 3000 double row radial spherical roller bearings. Near the gear end as the free end of the use of 32000 single-row radial short cylindrical roller bearings to adapt to the thermal expansion of the rotor when the axial displacement.

Synchronous gears: consisting of ring gear and hubs for easy adjustment of impeller clearance.

Body: from the chassis and the left and right wall composition. Left and right wall panels and installed in the left and right wall panels of the bearing, seal, etc., can be common to each other.

Base: medium and small fans are equipped with a common base, a large fan only with the base, easy to debug debugging.

Lubrication: gear with immersion, the use of splash lubrication bearings. Lubrication effect is good, safe and reliable.

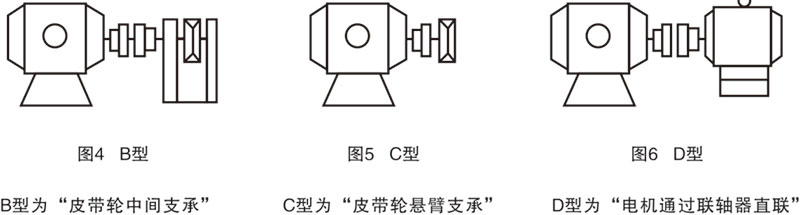

Transmission mode: mainly connected to the main coupling. If the performance specifications need, you can also use the V-belt transmission speed. Couplings use flexible coupling, can ease the impact and compensate for a small amount of axial deviation.

Product model descriptionVertical - the two rotor centerline of the blower in the vertical plane, the air flow for the horizontal flow (shown in Figure 3)

In order to facilitate the user to install and use, L1-L4 small fan with vertical and horizontal dual-use, L5 and L6 for the vertical, L7 to L11 large fan for the horizontal, horizontal structure of the inlet and outlet direction, such as from the strength, Into the next row as well. Our factory, vertical blower have been determined according to the direction of the exhaust to adjust the gap, such as users want to change into the exhaust direction, can be made in the purchase requirements, under the conditions allowed to change the strength.

Structure

Rotor: by the shaft, impeller, bearings, synchronous gear, coupling, sleeve and other components.

Impeller: the use of involute profile, the volume of high efficiency.

Bearing: near the coupling side as the positioning side of the choice of 3000 double row radial spherical roller bearings. Near the gear end as the free end of the use of 32000 single-row radial short cylindrical roller bearings to adapt to the thermal expansion of the rotor when the axial displacement.

Synchronous gears: consisting of ring gear and hubs for easy adjustment of impeller clearance.

Body: from the chassis and the left and right wall composition. Left and right wall panels and installed in the left and right wall panels of the bearing, seal, etc., can be common to each other.

Base: medium and small fans are equipped with a common base, a large fan only with the base, easy to debug debugging.

Lubrication: gear with immersion, the use of splash lubrication bearings. Lubrication effect is good, safe and reliable.

Transmission mode: mainly connected to the main coupling. If the performance specifications need, you can also use the V-belt transmission speed. Couplings use flexible coupling, can ease the impact and compensate for a small amount of axial deviation.

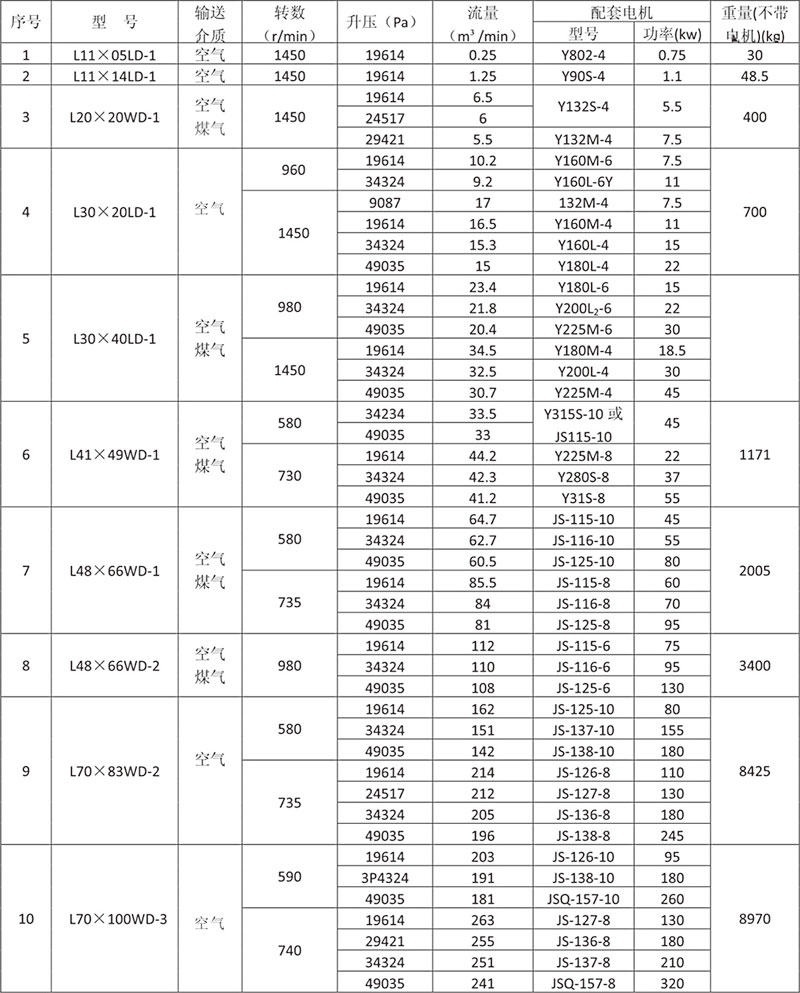

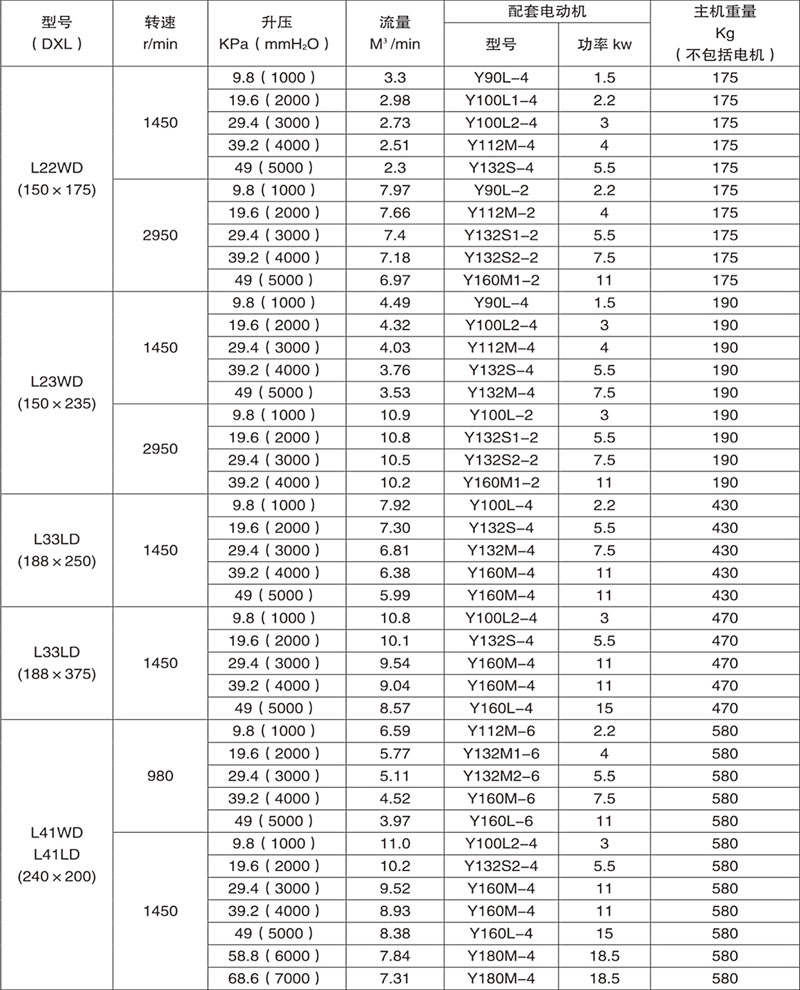

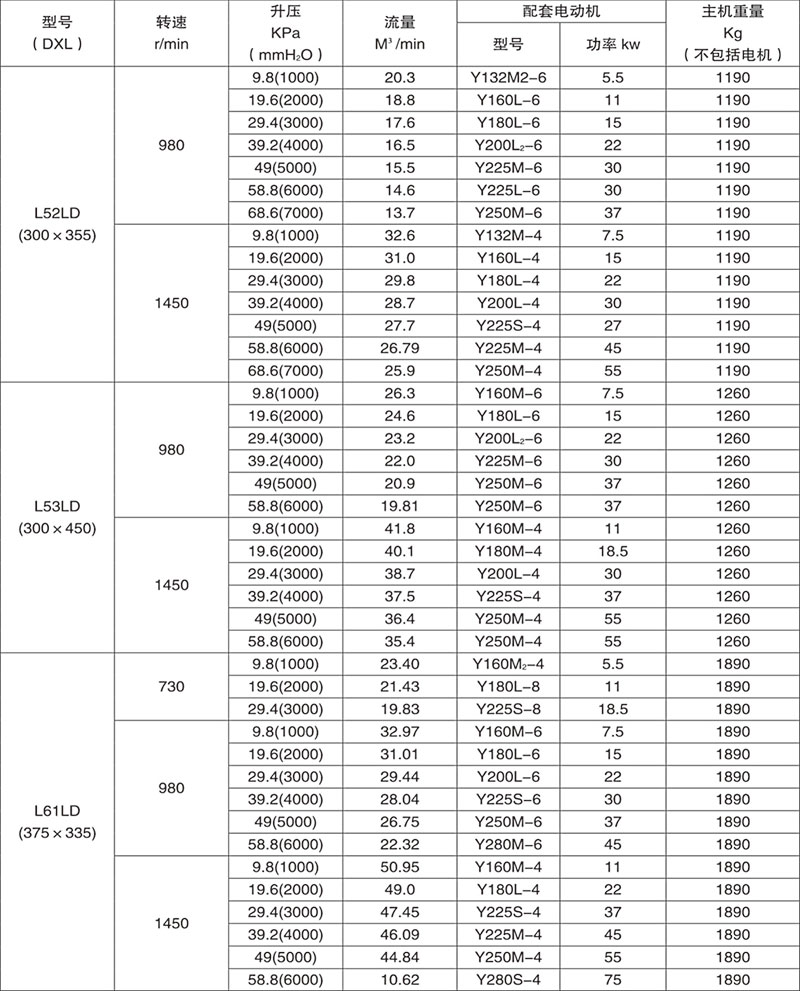

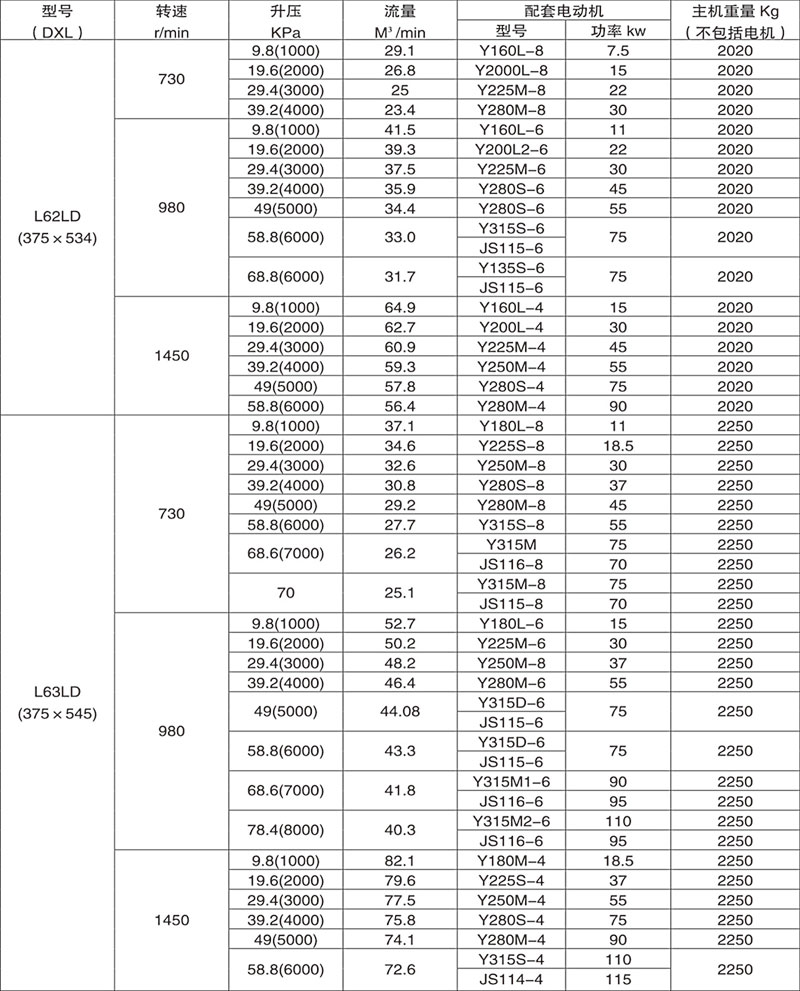

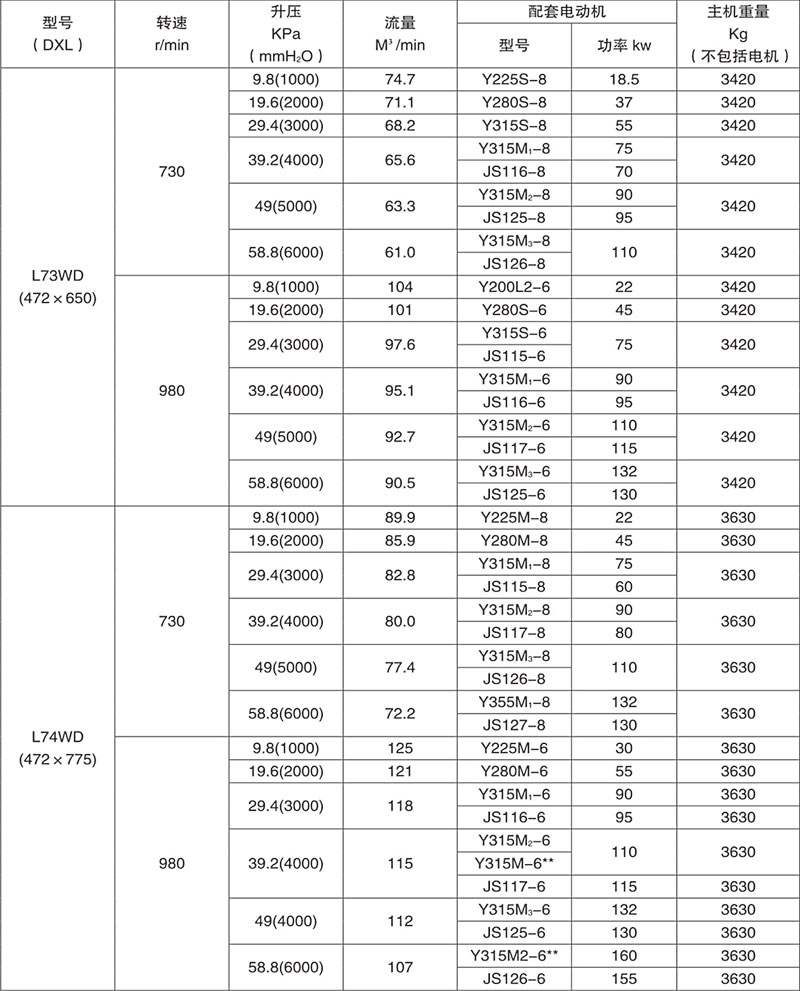

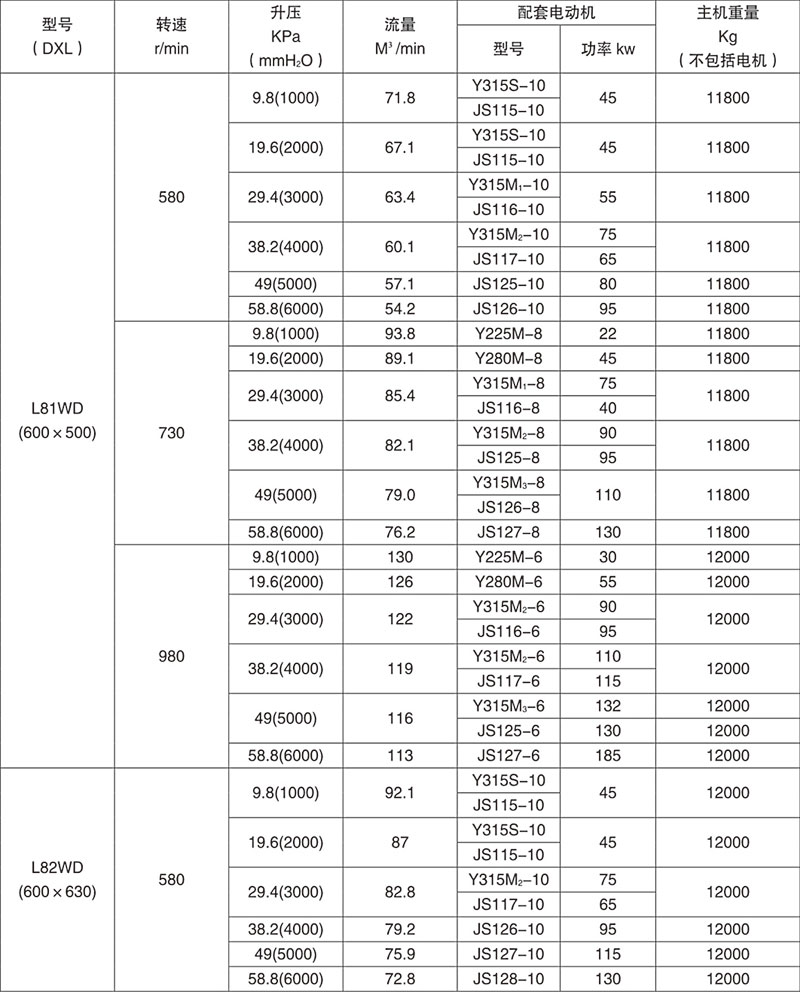

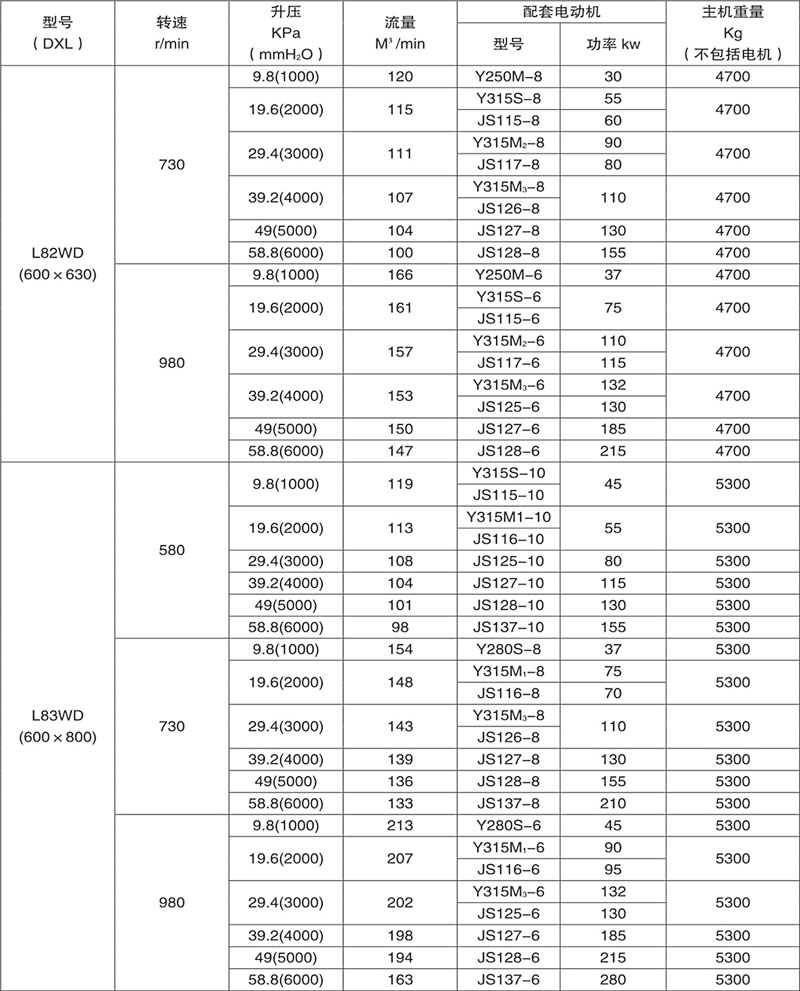

Roots blower performance parameters table

Clover blower

Features

1, forced air flow that changes, the flow change is small, the user can, as needed, in the rated boost range to adjust the outlet pressure.

2, the cylinder without lubrication, so the transmission medium does not contain oil.

3, three leaf fan air pulse is small, sealed, so low noise, leak less, high efficiency, smooth operation.

The main purpose

Widely used in sewage treatment, marine aquaculture, electricity, petroleum, chemical, metallurgy, cement, textile, food and other pneumatic conveying industry.

Requirements

1, the transport medium inlet temperature shall not be less than 40 ℃.

2, the medium particles content shall not exceed 100mg / m3, the maximum size of impurities shall not exceed half of the minimum gap of the impeller.

3, the use of booster shall not exceed the blower brand name calibration boost value.

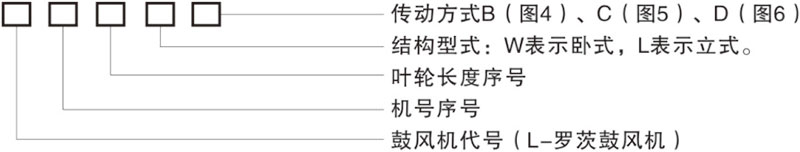

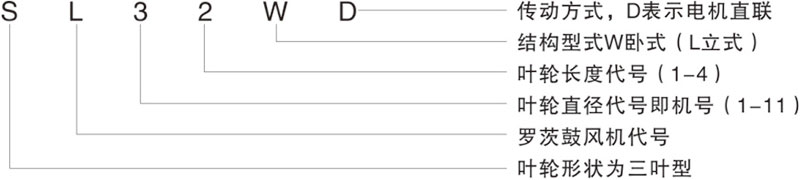

Model description and specification performance

1, product model description

Features

1, forced air flow that changes, the flow change is small, the user can, as needed, in the rated boost range to adjust the outlet pressure.

2, the cylinder without lubrication, so the transmission medium does not contain oil.

3, three leaf fan air pulse is small, sealed, so low noise, leak less, high efficiency, smooth operation.

The main purpose

Widely used in sewage treatment, marine aquaculture, electricity, petroleum, chemical, metallurgy, cement, textile, food and other pneumatic conveying industry.

Requirements

1, the transport medium inlet temperature shall not be less than 40 ℃.

2, the medium particles content shall not exceed 100mg / m3, the maximum size of impurities shall not exceed half of the minimum gap of the impeller.

3, the use of booster shall not exceed the blower brand name calibration boost value.

Model description and specification performance

1, product model description

2, specifications and performance

Conveying medium: air and other neutral gases

Intake air temperature: 20 ℃

Intake flow: 1.66-66.8m3 / min

Intake pressure: 101.3kPa

Relative humidity: 50%

Fan boost: 9.8-98kPa

When the delivery medium or the use of conditions and the above standard changes, please specify when ordering.

Conveying medium: air and other neutral gases

Intake air temperature: 20 ℃

Intake flow: 1.66-66.8m3 / min

Intake pressure: 101.3kPa

Relative humidity: 50%

Fan boost: 9.8-98kPa

When the delivery medium or the use of conditions and the above standard changes, please specify when ordering.